CAE Method Development

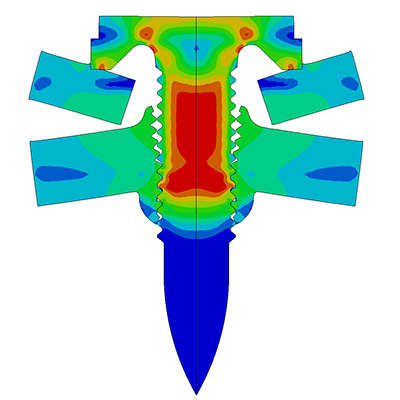

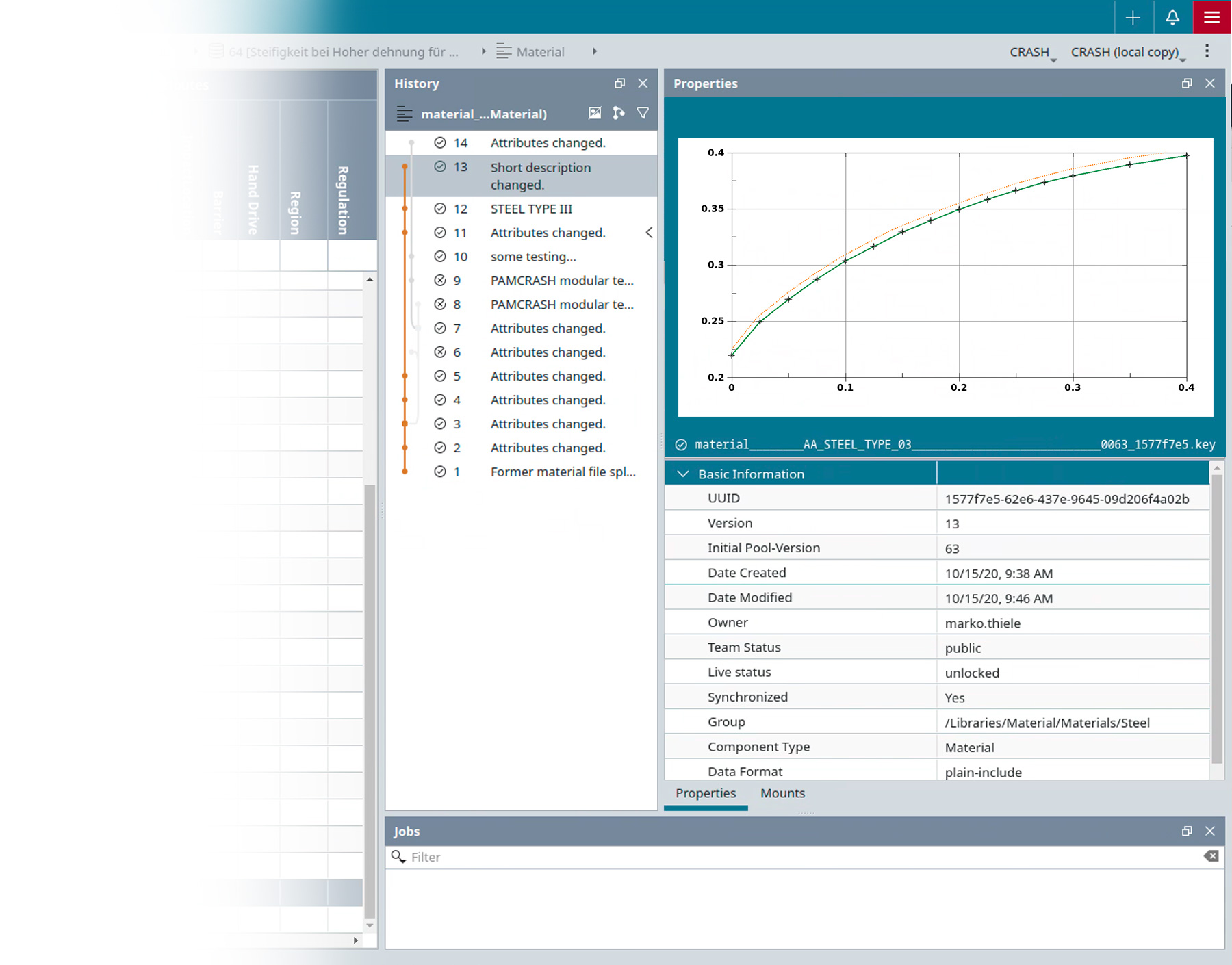

With the latest simulation methods, reality is becoming more and more detailed and realistic. This creates new requirements for the approach to modeling as well as for the numerical methods. This requires a constant sharpening and further development of existing methods and processes.

We are happy to support you here with our many years of experience in the form of services and consulting. Our strengths lie especially in the development of new processes in connection with complex simulation technologies. In addition to employees with a lot of in-depth experience, we have a large team of computer scientists who guarantee professional implementation. Due to our historical connection with DYNAmore, we have excellent expertise in the field of finie element methods.